Automatic Metallographic Grinding and Polishing Machine

Brand/Model: QATM / Qpol 250 A2

Description: An automatic grinding and polishing system used for surface preparation of metallographic samples. The robust aluminum alloy construction provides high durability and reliable long-term operation.

Operating Principle: Samples are processed on rotating discs at controlled speeds and directions to achieve grinding and polishing. Both the platen and sample holder head allow adjustable rotation speed and direction, ensuring uniform and repeatable surface preparation.

Specifications:

-

Disc diameter: 250 mm

-

Platen rotation speed: 30 – 600 rpm

-

Bidirectional rotation capability

-

Adjustable speed and rotation direction of the sample holder head

-

Digitally controlled automatic operation system

Automatic Vibratory Metallographic Polishing System

Brand/Model: QATM / Qpol Vibro

Description: An automatic vibratory polishing system designed for high-precision surface preparation of metallographic specimens. The device features a corrosion-resistant aluminum alloy body, ensuring durability and long-term operational stability.

Operating Principle: The system operates by generating controlled vibratory motion on the polishing disc, allowing uniform and deformation-free polishing of specimen surfaces under low mechanical force. Adjustable vibration frequency enables optimized polishing for various material types and preparation requirements.

Device Specifications:

Metallographic Sample Cutting Machine (Wet Cutting)

Brand/Model: QATM / Qcut 250 M

Description: A manual wet cutting machine designed for the precise sectioning of metallographic specimens without altering their microstructural properties. The corrosion-resistant aluminum body ensures durability and reliable operation.

Operating Principle: During cutting, continuous water cooling is applied to minimize heat generation and prevent microstructural damage. Manual control allows accurate and controlled cutting of samples for subsequent metallographic preparation.

Device Specifications:

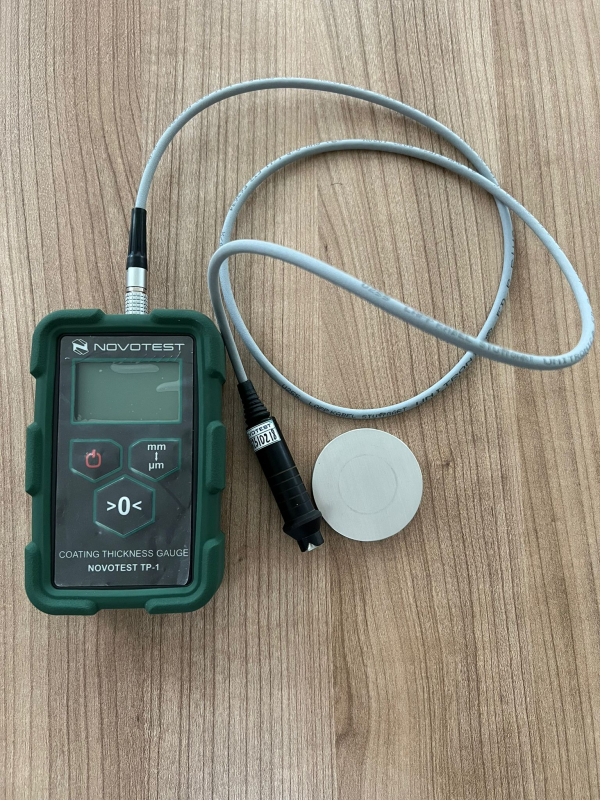

Coating Thickness Measurement Device

Brand/Model: NOVOTEST / TP-1M

Description: A portable, non-destructive device designed for measuring coating thickness on metal surfaces. It is capable of performing measurements on both ferrous and non-ferrous metallic materials.

Operating Principle: The device operates using magnetic induction and eddy current principles through dedicated probes. Coating thickness is measured accurately by placing the appropriate probe in contact with the surface.

Device Specifications:

-

Measurement range: 0 – 2000 µm

-

Two separate probes for ferrous and non-ferrous surfaces

-

Point surface roughness measurement with compatible probes

-

Dew point measurement capability

-

Contact surface temperature measurement

-

CE certified

Device Specialists:

Lecturer Ali Oktay Gül

E-mail: aoktay.gul@iste.edu.tr

Phone: 0 (326) 310 2840