AUTOMATIC UNIVERSAL HARDNESS DEVICE

Brand / Model: QATM / Qness 750 CS EVO

Description: The Qness 750 CS EVO is a universal hardness testing machine that automatically performs Rockwell, Brinell, and Vickers hardness measurements in accordance with international standards. Thanks to its high measurement accuracy, repeatability, and advanced automation capabilities, it provides reliable results for both laboratory use and industrial quality control applications.

Operating Principle: Hardness is a relative measure of a material’s resistance to localized plastic deformation caused by mechanical actions such as indentation, friction, scratching, or cutting. In indentation hardness testing, a conical or spherical standardized indenter is pressed into the material surface under a selected load. The size of the indentation formed as a result of the applied load is measured to calculate the hardness value. The hardness of the material is inversely proportional to the size of the indentation; the smaller the indentation, the harder the material.

Application Areas

-

Determination of hardness characteristics of metallic materials, parts, and components

-

Quality control and process verification during manufacturing

-

Definition and validation of target hardness values in new product development

-

Inspection of mechanical properties of safety-critical components

-

Documentation and reporting of hardness data related to production

-

Investigation of manufacturing defects, capital damage, or material loss

-

Use of hardness test results as references in legal cases and technical audits

Features

-

Equipped with a motorized load cell, capable of performing all load applications in the range of 0.3–750 kg (2.94–7358 N).

-

Automatic measurement system with auto light adjustment and auto focusing provided as standard.

-

Lens options: XLED 1, XLED 2, and XLED 5. All lenses feature an integrated ring light for indentation illumination and offer magnifications of 5x, 10x, 20x, 50x, and 100x.

-

Test height / throat depth: 395 mm / 220 mm.

-

Test table: Ø 100 mm.

-

Motorized turret system with 8 positions.

Concrete Compression Machine

Device Name / Model: Automatic Concrete Compression Testing Machine – HR-C2000/TS

Description: The Automatic Concrete Compression Testing Machine is a 2000 kN capacity concrete test press designed for reliable and consistent determination of the compressive strength of concrete and similar construction material specimens. The system is manufactured in compliance with EN, ASTM, and BS standards, and also meets CE requirements in terms of operator safety and occupational health. It offers automatic, semi-automatic, and manual operation modes via a digital readout unit and PC-based software.

Operating Principle: Compression testing is used to determine the behavior of materials under fracture loads. The specimen is compressed between pressure platens, and the deformation under various load levels is recorded. The testing press is supplied as standard with compression platens compliant with EN standards. When used with appropriate platens, the system also complies with ASTM C39. Tests can be performed directly via the digital readout unit or through a computer using dedicated software. In manual mode, measurement values are still displayed on the digital indicator.

System Components

-

Loading frame

-

Automatic hydraulic power unit

-

Digital data acquisition and control system

-

Spacer blocks (30 mm, 50 mm, and 80 mm)

-

Upper platen (with spherical seat)

-

Lower platen

-

Maximum pressure valves to prevent overloading

-

Limit switch to restrict piston stroke

-

Emergency stop button

-

Front and rear safety protective doors

Features

-

Adjustable loading rate control from 1 kN/s to 20 kN/s, depending on piston diameter

-

Capability to control two frames (optional)

-

Load-controlled testing capability

-

Real-time display of test graphs

-

Analog channels for different frame load cells

-

RS-232 serial port connection for PC interface

-

LCD display

-

Unit selection: kN and kgf

-

Unit system selection: SI and Metric

-

Multi-language support (Turkish and English)

-

Real-time clock and date

-

Free software for test control and printing of test reports

Indentation / Scratch Testing Device

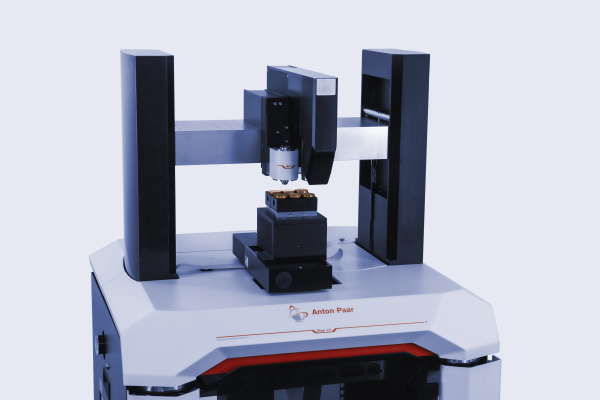

Brand / Model: Anton Paar – Step 501

Description: It is a multifunctional surface testing system designed to determine the mechanical properties of surfaces at the nano and micro scales. It enables nano hardness (indentation), micro hardness (Vickers), and micro scratch tests to be performed on a single platform. Thanks to its high-precision measurement capability and integrated optical microscope system, surface deformations can be examined in detail.

Operating Principle: The device applies controlled loads to the material surface using indenter tips. In nanoindentation tests, low loads (0–500 mN) are used to measure the elastic and plastic behavior of the surface, while higher loads (0–30 N) are applied in Vickers microhardness tests. In micro scratch tests, the indenter tip is moved across the surface in a controlled manner to analyze the adhesion, wear, and damage behavior of coatings and surfaces. After testing, the resulting indents and scratches are evaluated using the integrated optical microscope.

Application Areas

-

Materials science and engineering research

-

Coating and thin film analysis

-

Mechanical characterization of metals, ceramics, and polymers

-

Academic and industrial R&D studies

-

Quality control and surface performance evaluation applications

Tribometer (High-Temperature Wear Testing Device)

Brand / Model: Anton Paar / TH1000

Description: The high-temperature wear testing device is an advanced tribometer designed to investigate the friction and wear performance of metals, ceramics, coatings (PVD, CVD), composites, and lubricating materials under high-temperature conditions. With a maximum test temperature of up to 1000 °C, it enables reliable and repeatable analysis of material behavior under real operating conditions.

Operating Principle: The device measures the friction force and wear behavior between contacting surfaces under defined load, speed, and temperature conditions. During the test, controlled contact is established between the specimen and the counter body, while the temperature can be increased gradually. This allows scientific evaluation of changes in the coefficient of friction and wear characteristics as temperature rises. The measured data are used to assess the high-temperature performance of materials.

Application Areas

-

High-temperature performance analysis of metals, ceramics, composites, and coated materials (PVD, CVD)

-

Investigation of friction and wear behavior of lubricating materials at elevated temperatures

-

Simulation of real operating conditions for brake discs, bearings, cutting tools, and coating materials

-

Scientific study of the effect of temperature increase on friction and wear characteristics

-

Academic and industrial R&D studies

Features

-

Maximum test temperature: 1000 °C

-

Rotational speed: typically 0.3–600 rpm (optional up to 1500 rpm)

-

Maximum torque: approximately 450 mNm (depending on model and configuration)

-

Friction force range: typically 10 N with 0.03 mN resolution (optional up to 20 N)

Device Specialists:

1. Lecturer Ali Oktay Gül

E-mail: aoktay.gul@iste.edu.tr

Phone: 0 (326) 310 2840

2. Lecturer Mustafa Göktan Aydın

E-mail: goktan.aydin@iste.edu.tr

Phone: 0 (326) 310 2842